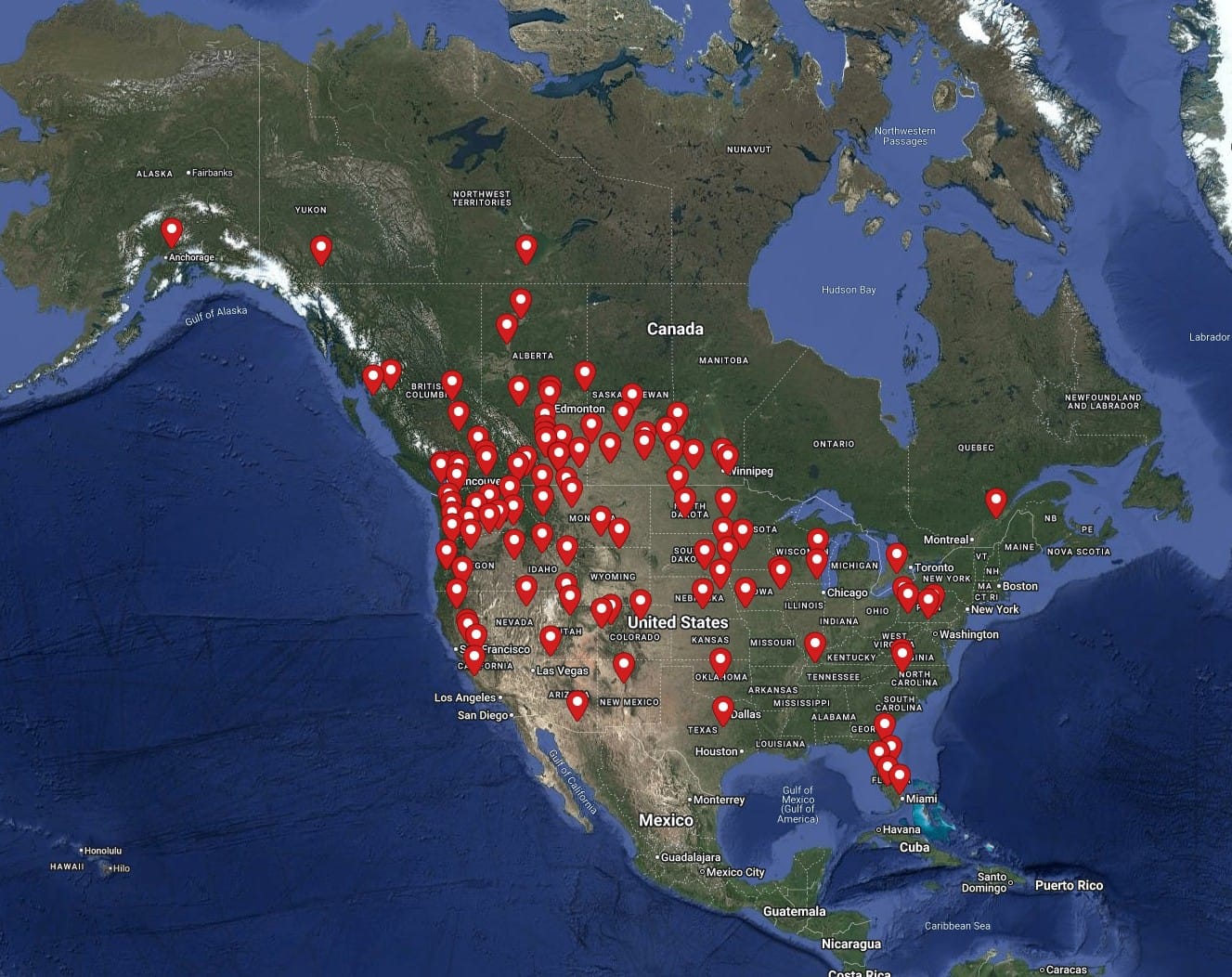

Search our North American network and get rolling faster.

Become a Dealer

Partner With Southland

Premium brand, strong margins, factory-backed support.

Become a Dealer

Partner With Southland

Premium brand, strong margins, factory-backed support.

WHY CHOOSE US

Founded by Monty and Shelly Sailer in 1980, Southland Trailer Corp. is now in the hands of their three sons—Jason, Ryan, and Scott Sailer—who have grown the Lethbridge-based company from about 70 employees in 2012 to more than 500 team members today. Notice how the language has changed over the years from employee to team member, contributing to the company’s culture and core values.

Founded by Monty and Shelly Sailer in 1980, Southland Trailer Corp. is now in the hands of their three sons—Jason, Ryan, and Scott Sailer—who have grown the Lethbridge-based company from about 70 employees in 2012 to more than 500 team members today. Notice how the language has changed over the years from employee to team member, contributing to the company’s culture and core values.

At Southland Trailers, we are committed to hard work, open communication, a positive attitude, calculated risk-taking, continuous improvements, and leading with humility/respect for every individual. We understand that these values set us apart from the competition and allow us to build trailers that meet the evolving needs of our customers.

As one of Canada’s largest trailer manufacturing companies, Southland Trailers understands that our success is not just about the product. It’s about our people. Our plant manager, T.J. Dow, captures this attitude: “it’s people, processes and then product. And if you work that way, it doesn’t matter what you’re building – you can be building trailers, pencils or rocket ships – and as long as you put your people first, the product will always be amazing, because the people care.” This commitment to our team members fosters a sense of respect and appreciation, which we believe is crucial for our continued growth and success.

Our commitment to LEAN manufacturing techniques and innovative designs allows us to build trailers that are not only reliable and durable but also efficient and easy to use. One thing that sets us apart is our direct access to owners and management. By maintaining close relationships with our customers and partners, we can better understand their needs and deliver exceptional service and support.

Our in-house engineering team and vertical integration allow us to design and build faster with cutting-edge technology. The material processing department supplies all plants for production before reaching final assembly, and the logistics team then consolidates trailers to form loads for dealer groups throughout Canada and the United States.

Southland Trailers will continue to lead the industry for years to come while supporting our community’s progress. We are committed to empowering people to do it better and are confident this approach will drive our vision for future growth.

Southland Trailers, empowering people to do it better.

Lead With Humility

We willingly lead with humility. Every member of the ST community – customers, partners, vendors, and fellow team members – should feel heard and valued. Every ST interaction should be comprised of authenticity, compassion, and respect.

Calculated Risk Taking

We take smart risks. We embrace the failures that lead to a better way. We are relentless in our intent to improve as individuals, and as the company we are building together.

Open Communication

Communication is how we build strong, trusting relationships with each other, and with our partners, customers, and communities. Respectful, transparent communication is not an option at ST—it is an obligation.

Hard Work

At ST we know nothing worthwhile is easy. Working hard means more than simply giving additional effort; it represents attitude and desire. It reflects a willingness to roll up your sleeves solve problems, and get the job done right.

Positive Attitude

We choose to be positive. Positivity is contagious and boosts the happiness, productivity, and creativity of those around us.

Continuous Improvement

ST is committed to getting better every day in all it does, as individuals and as teams. We relentlessly pursue continuous improvement and excellence in our products, processes, and services.

Follow us

Southland on Youtube